Research, Development and Innovation

Rother has always bet for the research and development. From the beginning of the company, it has invested in R&D and an Engineering Department in order to obtain the excellence for all the process of the company.

Continuous research to improve the quality of our products

Analyze and improve the operational processes of the company following a management system and a “Lean Remanufacturing” philosophy.

New calipers studies

Once a new caliper arrives to the market, it must be evaluated in order to check if it can be remanufactured with guarantees. A deep and complete study of the caliper is necessary; we must edit all the technical documentation, design and produce the repair components, make real functional tests and train our employees in order to introduce them the new caliper.

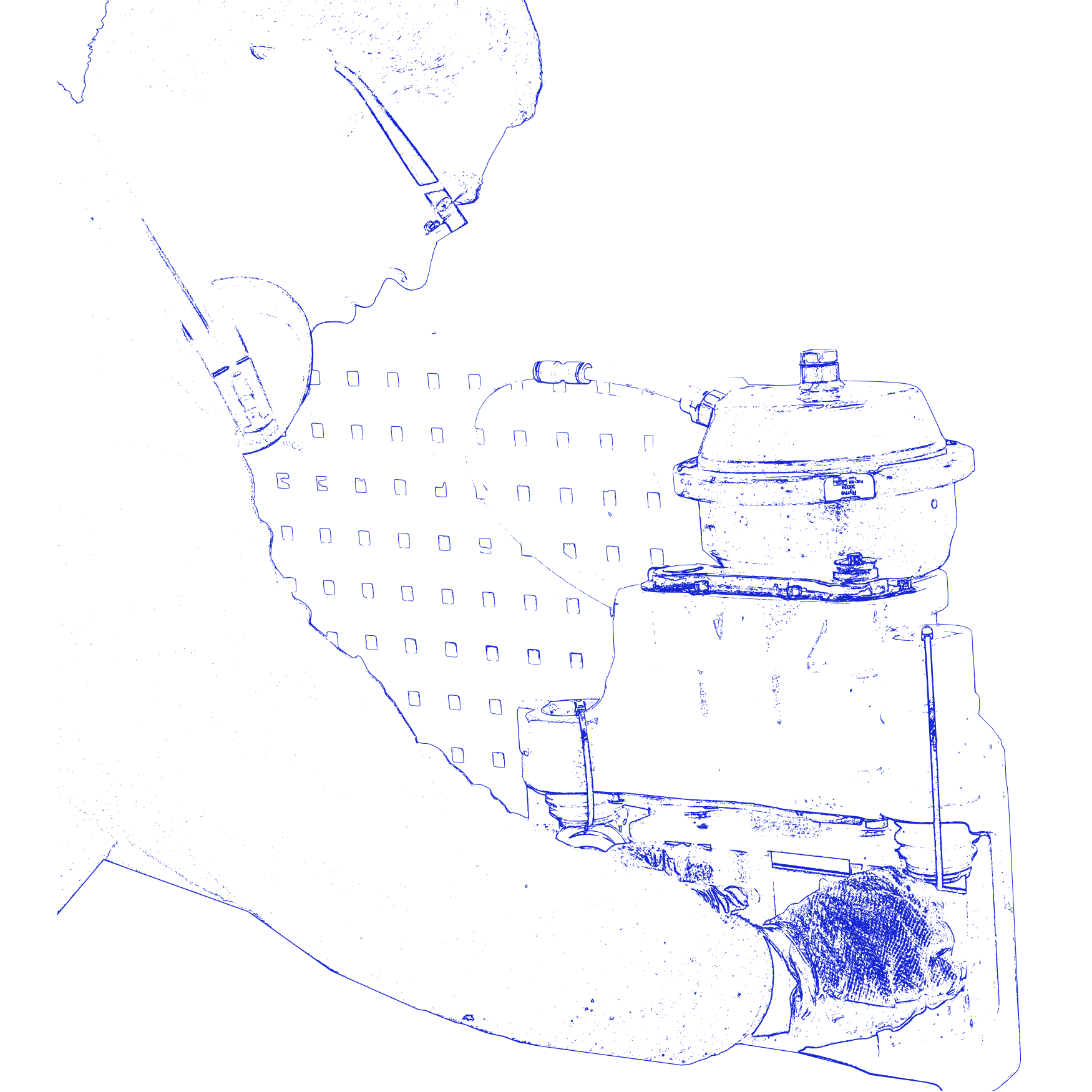

Creation of machinery

Our R&D Department has developed a testing bank for checking the functioning of the air brake calipers. It is employed at the end of the production line for certify that all the produced units by Rother have the correct performance.

New products research

We are constantly looking for new products which may be remanufactured. This way we can give some innovation to the spare parts sector. Actually, we have a new project based in the idea of remanufacture electronical components for commercial and industrial vehicles.

Testing bank

Simultaneous brake check of 8 units for each bank

Rother has developed its own testing bank to ensure the perfect functioning of all the remanufactured calipers.

After each testing process, the bank collects all the pressures and verification rates and edits a report.

Guide testing bank

Rother has also developed its own guide testing bank.

This bank ensure the perfect fitting of the caliper guides, rejecting minimum clearances.